Exploring the realm of preventive fleet care unveils a world where savvy maintenance practices lead to substantial cost savings. In this guide, we delve into the intricacies of how preventive fleet care can help fleet owners save thousands in the long haul.

As we uncover the key components, cost-effective strategies, and monitoring techniques, you’ll gain valuable insights into maximizing your fleet’s efficiency and minimizing expenses.

Importance of Preventive Fleet Care

Preventive fleet care is the practice of regularly maintaining and servicing fleet vehicles to prevent breakdowns and costly repairs. By staying ahead of potential issues, businesses can ensure their fleet runs smoothly and efficiently, saving time and money in the long run.

Benefits of Implementing Preventive Maintenance Practices

- Increased Vehicle Lifespan: Regular maintenance can extend the life of fleet vehicles, reducing the need for frequent replacements.

- Improved Safety: Well-maintained vehicles are less likely to experience mechanical failures on the road, reducing the risk of accidents.

- Enhanced Performance: Proper maintenance can optimize vehicle performance, leading to better fuel efficiency and overall productivity.

- Cost Savings: Preventive care helps identify potential issues early on, avoiding major repairs that can be expensive and disruptive to operations.

How Preventive Fleet Care Can Save Thousands

- Reduced Downtime: Regular maintenance minimizes unexpected breakdowns, keeping fleet vehicles on the road and avoiding costly delays in operations.

- Lower Repair Costs: Addressing small issues before they escalate can prevent the need for major repairs that come with a hefty price tag.

- Improved Resale Value: Well-maintained vehicles have higher resale or trade-in value, allowing businesses to recoup more of their investment when it’s time to upgrade their fleet.

- Avoidance of Penalties: Keeping vehicles in top condition helps avoid fines or penalties for non-compliance with regulations, saving businesses from unnecessary expenses.

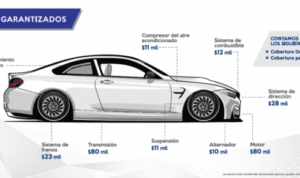

Components of Preventive Fleet Care

Regular inspections, scheduled maintenance, and proactive monitoring are essential components of an effective preventive fleet care program. By implementing these key components, fleet managers can maximize the lifespan of their vehicles, reduce downtime, and ultimately save thousands of dollars in repair costs.

Regular Inspections

Regular inspections play a crucial role in preventive maintenance by allowing fleet managers to identify potential issues before they escalate into major problems. By conducting routine inspections, such as checking tire pressure, fluid levels, and brake systems, fleet managers can address minor issues promptly and prevent costly breakdowns on the road.

Scheduled Maintenance Tasks

Scheduling routine maintenance tasks, such as oil changes, filter replacements, and brake inspections, can significantly contribute to cost savings in the long run. By following a regular maintenance schedule, fleet managers can ensure that their vehicles are operating at peak performance levels, reduce the risk of unexpected repairs, and extend the lifespan of their fleet.

Cost-Effective Maintenance Strategies

Maintaining a fleet of vehicles can be costly, but there are several strategies that can help save money in the long run. By implementing cost-effective maintenance practices, you can prevent unexpected breakdowns and reduce overall repair expenses.

Timely Repairs

When it comes to fleet maintenance, timely repairs play a crucial role in preventing costly breakdowns. Ignoring minor issues can lead to major problems down the line, resulting in expensive repairs or even vehicle replacement. By addressing maintenance needs promptly, you can avoid unnecessary expenses and keep your fleet running smoothly.

Quality Parts and Fluids

Using high-quality parts and fluids in your fleet vehicles can also lead to long-term cost savings. While cheaper alternatives may seem like a more budget-friendly option upfront, they often result in more frequent replacements and repairs. Investing in quality components can extend the lifespan of your vehicles, reducing maintenance costs and downtime in the process.

Monitoring and Tracking Maintenance

Monitoring and tracking maintenance tasks for fleet vehicles is essential to ensure they remain in optimal condition, operate efficiently, and avoid unexpected breakdowns. By staying on top of maintenance schedules, fleet managers can save time and money in the long run.

Utilizing Technology and Software for Tracking Maintenance Schedules

- Implementing fleet management software allows for centralized tracking of maintenance schedules for all vehicles in the fleet.

- Automated alerts and notifications can be set up to remind fleet managers of upcoming maintenance tasks, such as oil changes, tire rotations, and inspections.

- Utilizing GPS tracking technology can also help monitor vehicle usage and identify when maintenance is needed based on mileage or engine hours.

Data Analysis for Identifying Cost-Saving Opportunities

- Regularly analyzing maintenance data can help identify trends and patterns in vehicle breakdowns or repairs, allowing for preventive measures to be taken.

- By tracking maintenance costs and comparing them to industry benchmarks, fleet managers can identify areas where cost savings can be achieved, such as negotiating better service contracts or adjusting maintenance schedules.

- Utilizing predictive maintenance analytics can help forecast potential issues before they occur, reducing downtime and costly repairs.

End of Discussion

From understanding the importance of timely repairs to harnessing the power of data analysis, implementing preventive fleet care is not just a smart choice but a financially prudent one. Embrace these practices to unlock significant savings and ensure your fleet operates at its peak performance.

Frequently Asked Questions

What are some examples of cost-effective maintenance strategies?

Some examples include regular tire rotations, proper wheel alignments, and timely oil changes, which can prolong the lifespan of fleet vehicles and reduce maintenance costs.

How can monitoring maintenance tasks benefit fleet vehicles?

Monitoring maintenance tasks helps identify potential issues early, allowing for timely repairs and preventing costly breakdowns that could sideline vehicles and impact operations.

Why is using quality parts and fluids important for long-term savings?

Quality parts and fluids contribute to the overall health of fleet vehicles, reducing the risk of breakdowns and the need for frequent repairs, ultimately leading to long-term cost savings.