Exploring the reasons behind the widespread adoption of predictive maintenance technology by fleet managers, this article delves into the benefits, challenges, and key features associated with this innovative approach.

The content of the second paragraph that provides descriptive and clear information about the topic

Introduction to Predictive Maintenance Technology

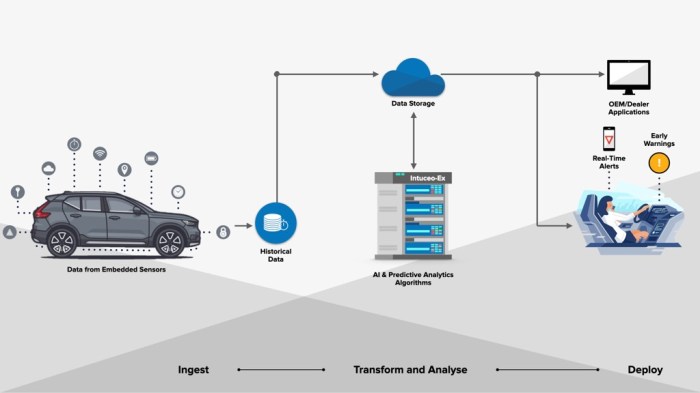

Predictive maintenance technology in the context of fleet management involves using data and analytics to predict when maintenance is needed on vehicles before a breakdown occurs. This proactive approach helps fleet managers avoid costly repairs and minimize downtime.Traditional maintenance approaches often involve scheduled maintenance based on mileage or time intervals, which can lead to unnecessary maintenance or unexpected breakdowns.

Predictive maintenance, on the other hand, relies on real-time data and machine learning algorithms to anticipate when parts are likely to fail, allowing for timely repairs or replacements.

Examples of Predictive Maintenance Tools

- Vehicle Telematics Systems: These systems track vehicle performance in real-time, providing data on engine health, fuel consumption, and other key metrics that can be used to predict maintenance needs.

- Predictive Analytics Software: Fleet managers can use software that analyzes historical data and trends to predict when specific components are likely to fail, allowing for proactive maintenance planning.

- Remote Diagnostics: Some systems can remotely monitor vehicle diagnostics and performance, alerting fleet managers to potential issues before they escalate.

Benefits of Predictive Maintenance Technology for Fleet Managers

Predictive maintenance technology offers a wide range of benefits for fleet managers, helping them streamline operations, reduce costs, and improve overall efficiency.

Reducing Downtime for Fleet Vehicles

Predictive maintenance technology plays a crucial role in reducing downtime for fleet vehicles by predicting potential issues before they occur. By monitoring the health of vehicles in real-time and analyzing data patterns, fleet managers can schedule maintenance tasks proactively, avoiding unexpected breakdowns and minimizing downtime.

This proactive approach ensures that vehicles are kept in optimal condition, reducing the risk of costly repairs and maximizing fleet availability.

Cost-Saving Benefits

One of the key advantages of predictive maintenance technology is its cost-saving benefits for fleet managers. By identifying maintenance needs in advance, fleet managers can avoid unnecessary maintenance tasks and replace parts only when needed. This targeted approach helps in reducing overall maintenance costs, optimizing spare parts inventory, and extending the lifespan of fleet vehicles.

Additionally, by preventing major breakdowns through predictive maintenance, fleet managers can save on expensive repairs and minimize operational disruptions, resulting in significant cost savings in the long run.

Improving Overall Fleet Efficiency

Predictive maintenance technology contributes to improving overall fleet efficiency by ensuring that vehicles are operating at peak performance levels. By monitoring key performance indicators and analyzing data trends, fleet managers can identify areas for improvement, optimize maintenance schedules, and enhance vehicle performance.

This proactive maintenance approach not only increases the lifespan of fleet vehicles but also enhances fuel efficiency, reduces emissions, and improves driver safety. Ultimately, predictive maintenance technology helps fleet managers achieve higher levels of productivity, reliability, and customer satisfaction.

Implementation of Predictive Maintenance Technology in Fleet Management

Implementing predictive maintenance technology in fleet management involves several steps to ensure a smooth integration and maximize the benefits for fleet managers. However, challenges may arise during the process, requiring careful planning and effective strategies to overcome them.

Integrating Predictive Maintenance Technology into Fleet Management System

- Assess Current Maintenance Practices: Evaluate existing maintenance processes and identify areas where predictive maintenance can be integrated.

- Choose the Right Technology: Select a predictive maintenance solution that aligns with the specific needs and goals of the fleet.

- Train Personnel: Provide training to fleet managers and technicians on how to use the new technology effectively.

- Establish Data Collection Methods: Set up systems for collecting and analyzing data to predict maintenance needs accurately.

Challenges Faced by Fleet Managers

- Resistance to Change: Some team members may be resistant to adopting new technology, requiring effective communication and training.

- Data Quality Issues: Ensuring the accuracy and reliability of data collected for predictive maintenance can be a challenge.

- Integration with Existing Systems: Integrating predictive maintenance technology with current fleet management systems may require technical expertise and resources.

Tips for Effective Rollout of Predictive Maintenance Technology

- Start Small: Begin with a pilot project to test the technology before scaling it across the entire fleet.

- Collaborate with Providers: Work closely with technology providers to ensure a smooth implementation process and address any issues that may arise.

- Monitor Performance: Continuously monitor the performance of the predictive maintenance system and make adjustments as needed to optimize results.

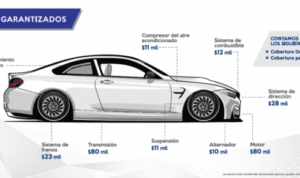

Key Features of Predictive Maintenance Technology for Fleet Management

Predictive maintenance technology offers several key features that fleet managers should consider when choosing a solution for their operations. These features can help optimize fleet performance, reduce downtime, and ultimately save costs.

Real-Time Monitoring

Real-time monitoring is a critical feature of predictive maintenance technology for fleet management. This feature allows fleet managers to track the health and performance of their vehicles in real-time, enabling them to identify potential issues before they escalate. By monitoring key metrics such as engine health, fuel efficiency, and tire pressure, fleet managers can proactively address maintenance needs and prevent unexpected breakdowns.

Data Analysis and Reporting

Another essential feature of predictive maintenance technology is robust data analysis and reporting capabilities. Advanced analytics tools can process large amounts of data collected from vehicles and generate actionable insights for fleet managers. By analyzing trends, patterns, and anomalies in the data, fleet managers can make informed decisions about maintenance schedules, part replacements, and overall fleet operations.

Predictive Analytics

Predictive maintenance technology often incorporates predictive analytics algorithms that can forecast equipment failures based on historical data and machine learning models. By leveraging predictive analytics, fleet managers can anticipate maintenance needs, schedule repairs during off-peak hours, and optimize resource allocation.

This proactive approach helps prevent costly downtime and extends the lifespan of fleet assets.

Integration with IoT Devices

Many predictive maintenance solutions integrate with Internet of Things (IoT) devices installed in vehicles to collect real-time data on performance and condition. IoT sensors can monitor engine temperature, oil levels, and other critical parameters, providing valuable insights for maintenance planning.

By leveraging IoT technology, fleet managers can streamline data collection processes and enhance the accuracy of predictive maintenance predictions.

Mobile Accessibility

Mobile accessibility is another key feature that fleet managers should look for in predictive maintenance technology. Mobile applications allow managers to access maintenance data, receive alerts, and make informed decisions on the go. With mobile accessibility, fleet managers can stay connected to their fleet operations from anywhere, ensuring timely response to maintenance issues and improved overall efficiency.

Wrap-Up

In conclusion, predictive maintenance technology has revolutionized the way fleet managers maintain their vehicles, leading to increased efficiency, reduced downtime, and significant cost savings. By embracing this technology, fleet managers can stay ahead of maintenance issues and ensure optimal performance of their fleets.

Question & Answer Hub

What are the key benefits of predictive maintenance technology for fleet managers?

Predictive maintenance technology helps in reducing downtime, cutting costs, and enhancing overall fleet efficiency by detecting issues before they escalate.

How can fleet managers effectively implement predictive maintenance technology?

Fleet managers should start by defining their goals, selecting the right technology, training their team, and continuously monitoring and adjusting their maintenance strategy.

What role does real-time monitoring play in predictive maintenance for fleets?

Real-time monitoring allows fleet managers to track the health of their vehicles continuously, enabling proactive maintenance actions to be taken before critical failures occur.